Auxiliary Sponsons for a Coot Amphibian

WHAT ARE THEY?

Molt

Taylor designed the Coot with sponsons on each side of the hull

to give lateral stability on the water, thereby obviating the need for

wing-tip floats. The wings are mounted on the ends of these sponsons,

so they might not be immediately apparent. Auxiliary sponsons have recently

been added to a few Coots to provide additional buoyancy and to keep all

water spray away from the propeller. They have been used instead of spray

rails as an optional way to improve the water performance of some Coots

that end up being heavier than the designer's recommendation of 1450 pounds

empty weight.

WHAT DO THEY ACCOMPLISH?

1) Shorten time to mount the bow wave by 6 seconds;

2) Shorten time to take off water by 5 seconds;

3) Eliminate water spray damage to the propeller;

4) Provide a convenient platform for entry or disembarking;

5) Improve cruise speed by 7 to 10 mph. *

*This last benefit was totally unexpected, but has been confirmed by GPS in at least 3 Coots. The numbers for the first two benefits were observed in my own Coot, which weighs 1650 lb. empty. These benefits might be less impressive in lighter Coots.

WHERE AND HOW ARE THEY MOUNTED?

As shown above, they are mounted along the sides of the hull such that their bottom surfaces are flush with the bottom of the hull. Their aft ends should be even with the step of the hull. They may be either fiberglassed in place permanently, or bolted in place semi-pemanently, using the same holes along the bottom of the hull that would be used for mounting the spray rails. Of course, the latter method requires one to build suitable flanges out of fiberglass cloth that will carry the large water forces into the sides and bottom of the hull. This is shown in the simple cross-sectional sketch below:

Attach the top flange to the hull with 3/4" stainless steel (ss) flathead machine screws (A/C Spruce # MS24693C274) with 1032 threads and countersunk washers (# A3235-SS-020). Retain these inside the hull with appropriately sized large washers and elastic stop nuts. Attach the bottom flange with 1032 thread bolts and countersunk washers at 3" intervals, picking up the original spray rail nut plates that were built into the inside of the hull.

HOW DOES ONE BUILD THE AUXILIARY SPONSONS?

The permanently installed sponsons can be layed up on the inside of suitably made molds, in which case their centers are air-filled, except where they are supported internally with ribs. In contrast, the removable sponsons are made without molds by covering suitably shaped blocks of styrofoam with fiberglass. The latter technique requires use of a hot wire to form a reasonbly accurate shape, and is described in detail below, as originally developed by John Hessler:

1) Order large-cell, blue styrofoam (A/C Spruce cat. # 01-10800) in two blocks, each 16" X 8 " X 67" long.

2) Build two templates out of 1/16" formica with the following airfoil shape, in inches, where left is the leading edge:

Top surface: ---1.5 - 2.2, 2.5, 2.8, 3.0, 3.2, 3.35, 3.60, 3.75, 4.0, 4.15, 4.25, 4.5, 4.75, 4.85, 4.95, 5.0, 5.0, 5.0, 4.95, 4.90,

Chord line: ------1----2----3----4---5----6----7-----8-----9----10----11--12---14---16-18---20---22---24--26---28----30-

Lower surface: 0.8, 1.15, 1.3, 1.5, 1.6, 1.7, 1.75, 1.75, 1.75, 1.75, 1.75, 1.8, 1.85, 1.9, 2.00, 2.05, 2.1, 2.15, 2.1, 2.05, 2.05,

Continue to draw the template aft with the dimensions shown below:

Top surface: ---4.85, 4.75, 4.5, 4.35, 4.2, 3.9, 3.7, 3.4, 3.2, 2.95, 2.7, 2.4, 2.0, 1.75, 1.4, 1.15, 0.75, 0.5, 0.0

Chord line: ------32--34---36---38--40--42--44--46--48--50---52---54--56---58---60---62---64---66--68.

Lower surface: 2.0, 1.85, 1.8, 1.75, 1.6, 1.4, 1.3, 1.2, 1.0, 0.8, 0.65, 0.5, 0.4, 0.35, 0.3, 0.30, 0.30, 0.25, 0.0.

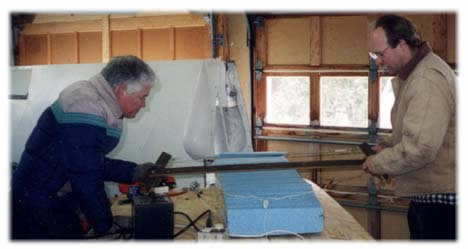

3) Buy, borrow or build a "hot wire" system for cutting styrofoam. It consists of 50-lb. test steel fishing line, mounted under spring tension in a wooden frame, powered by a 12-volt battery charger controlled through a 110 volt dimmer switch. Adjust the dimmer switch to keep the wire hot enough to cut your foam at 2 to 3 mm/second. With the templates lightly glued in perfect alignment on either side of the 14" wide styrofoam, bring the hot wire down onto the formica templates, which resist the hot wire well, and cut slowly, steadily and carefully all around the templates, as shown below:

4) Before you throw out the styrofoam scraps, take two pieces 55" to 56" long and make them into chines with a cross section of a right-angled triangle 1.4" X 2" in size. Glue one along the outer edge of each sponson, flush with its aft end, so that water will be deflected down by this lateral chine.

5) Mark and trim excess styrofoam off the inner aspect of each sponson so it will fit against the Coot hull along its entire length. This should give each auxiliary sponson a width of 13" at the front end and 11" at the aft end.

6) Strengthen each sponson in the following areas with glass cloth (AS cat. # 7781) or tape (AS cat. #45TAP3):

Chines: Along the lower surfaces, glass over the chines with 1 layer of 3 " tape; then add another layer of 4" tape.

Trailing edges: Wrap 2 layers of glass cloth around the aft ends, reaching 6 " forward on tops & bottoms.

Top flange: Cut 3" tape in half lengthwise; fit both of them to the top inner sponson contour after it has been placed, inner side down, on a curved sheet of plastic or aluminum curved like the hull and coated with mold release compound. Apply 3 layers of crow-foot weave (#7781) cloth 3" to 4" wide over the top flange tapes; let epoxy soak into each layer.

Bottom flange: Retrieve excess styrofoam left over from the inner part of the sponson cut away in step 5. Use this to establish a bottom surface contour adjacent to your inverted sponson. Align and temporarily bond them with glue or long pins. Apply mold release. Then apply 3" tape, followed by 4" tape over the gap, letting epoxy soak through it each time.

Bottom surface: Prepare this surface, especially toward the aft, by perforating the styrofoam core material with small holes (1/8" deep every inch or so), using either a "woodpecker" roller or a small board covered with brads. Apply a slurry of epoxy mixed 50-50 with microballoons, using a squeegee to scrape away the excess. Wait a few hours until the slurry becomes tacky before moving on to step 7. This gives better adherence of cloth to the styrofoam core material.

7) Cover the inner surface of both sponsons with 1 layer of #7781 cloth. Cover all other surfaces with 2 layers of 7781. Then cover all other surfaces with a 3rd layer of light deck cloth (#1080), keeping it as smooth as possible.

8) When all is dry, trim excess material off the flanges, sand all surfaces to a smooth finish, and paint. Follow mounting instructions given above.

Postscript: By now you should have 4 cubic feet (248 lb.) of flotation.

If the sponsons weigh 24 lb., the net flotation will be 224 lb. Then go

out and test how well they work with a GPS and stop-watch under exactly

the same conditions as before you mounted them. If you send me your results

I will post them here!